As Harley riders, we all want our motorcycles to run as smoothly as possible. The Harley compensator is a key part of the engine, and it plays a crucial role in keeping our bikes running in top condition.

The compensator absorbs shock from the crankshaft to the primary drive, reducing vibration, protecting the transmission, and smoothing power delivery to the rear wheel.

In this article, we’ll explore the what and why of the Harley compensator and discuss what it does to keep our bikes running at peak performance. Whether you’re a new Harley rider or an experienced enthusiast, you won’t want to miss this valuable insight. Let’s dive in and discover the power of the Harley compensator.

What does the compensator do on a Harley?

Harley-Davidson motorcycles are widely renowned for their powerful engines, beautiful designs, and distinct exhaust notes. If there’s one thing that often gets overlooked and unnoticed, then it is surely the compensator. A compensator is a mechanical device that is normally found in the primary drive system of a motorcycle engine. In the case of a Harley-Davidson bike, the compensator is located in the primary drive, which is largely responsible for transmitting power from the engine to the transmission.

The purpose of the compensator in a Harley-Davidson motorcycle is to absorb the shock and vibrations that get generated by the engine and transmitted through the primary drive system. This gets accomplished by using a set of springs and weights that are designed to counteract the torque generated by the engine.

The importance of a compensator cannot be overstated as without it, the primary drive system will be subjected to excessive stress and wear and tear. This can ultimately result in premature failure of the primary drive system, which can be both costly and dangerous.

In addition to the primary function of reducing shock and vibrations, a compensator will also serve to provide smoother power delivery to the transmission. This is possible by reducing the pulsing effect that is generated by the engine, which results in a jerky feeling when accelerating.

There are different types of compensators available for Harley-Davidson bikes, including stock compensator, hydraulic compensators, and aftermarket compensators. Each type of compensator has its own advantages and disadvantages. The choice of compensator will depend on your specific needs and preferences.

Design specifications and materials used for the construction of compensators

The compensator is a key component of the primary drive system of a Harley-Davidson motorcycle. It is tasked with absorbing shocks and vibrations generated by the engine and providing smoother delivery to the transmission.

Design specifications

The design of the compensator is important to its performance and reliability. The compensator is designed for absorbing the shock and vibrations generated by your Harley-Davidson bike’s engine. The design specifications of the compensator are also important for ensuring its longevity and effectiveness.

#1. Weight and size of cam assembly

The weight and size of the cam assembly need to be carefully designed to make sure that it is capable of holding the torque generated by the engine.

#2. Number of springs in the spring pack

Another key design specification is the number of springs in the spring pack. The number of springs will vary depending on the specific model of the bike. Typically, they range from five to seven. The configuration of the springs should be carefully designed to make sure that they can absorb shock and vibrations evenly and that they don’t create excessive stress on any individual component.

#3. Bearing and bushing material

The bearings and bushings used in the compensator are designed for reducing friction and wear between the moving parts. They’re often made using plastic materials such as nylon and polyurethane, which have excellent wear and corrosion resistance properties.

#4. Spring configuration

The compensator uses a set of springs and weights that are tuned carefully to counteract the torque generated by the engine. The spring and weight configuration are designed in a way to provide smooth and consistent power delivery to the transmission.

#5. Mounting and alignment

The compensator is mounted to the engine and transmission using a set of bolts and spacers. The mounting and alignment are critical to the compensator’s performance, as any misalignment can cause excessive wear and premature failure.

Materials used in compensator construction

The compensator typically consists of two primary components – the spring pack and the cam assembly. The spring pack is made using a set of springs that are designed to absorb shock and vibrations, whereas the cam assembly is responsible for transmitting power from the engine to the transmission.

The materials used in the construction of compensators will be critical in ensuring the long-term durability and reliability of the component. Generally, the spring pack is made using high-grade steel whereas the cam assembly is made using a combination of steel and aluminum.

The springs used in the spring pack are commonly made using chrome-silicon steel, which is known for its high tensile strength and fatigue resistance. This allows the springs to easily withstand the constant stress and movement associated with the primary drive system.

#1. Steel

Steel is a robust material widely used in the construction of Harley-Davidson compensators. It is durable, resistant to wear and tear, and can easily withstand high levels of stress and torque generated by the engine.

#2. Aluminum

Aluminum is a lightweight material that is often used for the construction of high-performance compensators. It is ideal for reducing the overall weight of the Harley while maintaining the required strength and durability.

#3. Carbon fiber

Carbon fiber is a high-strength material that is commonly used in the construction of lightweight and high-performance compensators. It is incredibly strong and lightweight, which makes it ideal for racing and high-performance applications.

How does the compensator on a Harley-Davidson bike work?

The compensator forms a critical part of the working mechanism of the primary drive system on a Harley-Davidson bike. Its primary function is to absorb shocks and vibrations generated by the engine, which, in turn, ensures that the primary drive system is protected from excessive wear and tear.

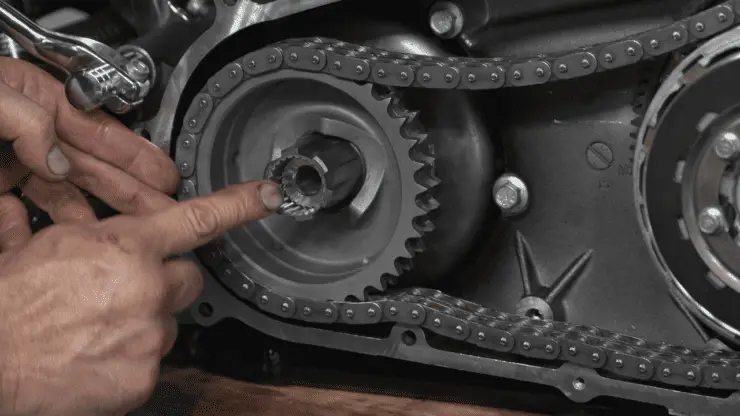

The compensator is located in the primary drive system, the component responsible for transmitting power from the engine to the transmission. The primary drive system consists of numerous components, including the engine sprocket, the clutch, the primary chain, and the compensator.

When the engine is running, it’ll generate a significant amount of torque and vibration that gets transmitted through the primary drive system. Without a compensator, the torque and vibration would cause excessive stress and wear on the primary drive components, eventually resulting in premature failure.

The compensator works by utilizing a set of springs and weights to counteract the torque generated by the engine. The springs are located in the spring pack, which is positioned behind the cam assembly. The cam assembly is connected to the engine sprocket and is responsible for transmitting power to the primary chain.

As the engine continues to produce torque, the cam assembly will start to rotate. This rotation will cause the weights, which are located on the cam assembly, to move outward. As the weights start moving outwards, they’ll compress the springs in the spring pack, absorbing the shock and vibrations generated by the engine.

The design of the compensator will be key to ensuring that it can effectively absorb the shock and vibrations generated by the engine. The number and configuration of the springs in the spring pack and the weight and size of the cam assembly should be carefully engineered to ensure that the compensator can handle the stress and movement associated with the primary drive system.

In addition to its primary function of absorbing shock and vibrations, the compensator also helps to provide smoother power delivery to the transmission. By reducing the “pulsing” effect generated by the engine, the compensator helps to provide a more stable and predictable power delivery, resulting in a smoother and more comfortable ride.

Benefits of the compensator on a Harley-Davidson motorcycle

Harley-Davidson motorcycles are known best for their incredible power and performance, but they also generate significant levels of torque and vibration, which can cause excessive wear and tear on the primary drive system. This is where the compensator comes into the picture. It offers a wide range of benefits for Harley-Davidson motorcycles. Here are some of the primary benefits of the compensator on a Harley-Davidson motorcycle –

#1. Reduced wear and tear

The primary drive system is typically responsible for transmitting power from the engine to the transmission. Without a compensator, the torque and vibration generated by the engine can cause excessive wear and tear on the primary drive component. This can ultimately lead to premature failure. The compensator absorbs the shock and vibration, protecting the primary drive system from damage and ensuring that it remains reliable and durable.

#2. Improved power delivery

The compensator helps in providing smoother power delivery to the transmission. By reducing the pulsating effect generated by the engine, the compensator will help to provide a more stable and predictable power delivery, resulting in a smoother and more comfortable ride.

#3. Enhanced performance

The compensator can also help in enhancing the performance of the motorcycle. By reducing the stress and movement associated with the primary drive system, the compensator will also help in improving the efficiency of the engine and transmission. This will result in better acceleration and overall performance.

#4. Increased comfort

The compensator will also help in increasing rider comfort by reducing the amount of vibration transmitted through the motorcycle. This will help in reducing rider fatigue and improve overall ride quality, especially on longer rides.

#5. Reduced maintenance costs

By reducing the primary drive system from excessive wear and tear, the compensator will help to reduce maintenance costs over the life of the motorcycle. This will ultimately result in significant savings for you over time, as you won’t need to replace primary drive components as frequently.

Maintenance of compensator on a Harley-Davidson bike

Regular maintenance of a compensator is necessary to ensure that it continues to function properly and protect the primary drive components on your Harley from excessive wear and tear. There are certain tasks that you will need to carry out to ensure that you maintain and take care of the compensator.

#1. Regular inspection

The first step in maintaining the compensator of your Harley-Davidson bike would be to regularly inspect it for any signs of wear or damage. This includes frequently checking for any cracks or excessive wear on the teeth of the compensator assembly. If any damage is found, the compensator needs to be replaced immediately.

#2. Regular lubrication

The compensator needs to be lubricated regularly to make sure that it operates smoothly and quietly. It includes adding grease to the needle bearings inside the compensator assembly and lubricating the splines on the clutch hub and compensator nut.

#3. Torque according to the specifications

The compensator nut needs to be torqued to the manufacturer’s specifications to ensure that it is properly secured. Over-tightening or under-tightening the compensator nut could cause damage to the primary drive components and affect the overall operation of the compensator.

#4. Check the belt tension

The belt tension needs to be checked regularly to ensure that it is within the manufacturer’s specifications. An overly tight or loose belt could cause excessive wear and tear on the primary drive components, including the compensator.

#5. Replacement if needed

The compensator on your Harley-Davidson motorcycle has a limited lifespan, and it’ll eventually have to be replaced. The manufacturer recommends that you should replace the compensator once every 50,000 miles to ensure that it continues to offer reliable protection to the primary drive system. If you don’t replace the compensator on your Harley at the right time, you are inviting issues that could have been easily avoided.

How to replace the compensator on a Harley-Davidson bike

The compensator on a Harley-Davidson motorcycle is a key component that requires regular maintenance. It is responsible for absorbing shock and reducing vibration. Over time, the compensator on your Harley can become worn or damaged, which affects its ability to perform at its optimal level. This is where you will know that it is time to replace the compensator on your Harley. You can either take your Harley-Davidson motorcycle to a professional and get the compensator replaced. But if you want to take the DIY route, then you will find it to be easier than you may think. Although, you will need to know the right steps. Here are the steps to replace the compensator on your Harley-Davidson motorcycle.

Before you start the replacement process, it will be important to ensure that you’ve got the necessary tools and equipment. You will need a torque wrench, a socket set, a primary cover gasket, and a compensator locking tool.

Step 1: Drain the primary oil

To start, you will need to drain the primary oil by removing the drain plug located at the bottom of the primary cover. Allow the oil to completely drain before you proceed to the next step.

Step 2: Remove the primary cover

You should then remove the primary cover by removing the bolts located around the perimeter of the cover. Once the bolts have been removed, you should gently pry the cover away from the engine.

Step 3: Remove the compensator nut

Using a torque wrench and a socket set, you should remove the compensator nut by turning it counterclockwise. Once you have removed the nut, the compensator assembly can be easily pulled away from the engine.

Step 4: Remove the compensator

Then, you can easily remove the compensator using a compensator tool to hold the compensator in place while removing the retaining bolt. Once the retaining bolt has been removed, the compensator can be pulled away from the engine.

Step 5: Install the new compensator

You can then install the new compensator by aligning the splines on the compensator by aligning and then by aligning it on the engine output shaft. Insert the retaining bolt and tighten it to the manufacturer’s torque specifications using a torque wrench.

Step 6: Install the compensator nut

Install the compensator nut by turning it clockwise and tightening it to the manufacturer’s torque specifications using a torque wrench.

Step 7: Install the primary cover

Install the primary cover by aligning it with the engine and securing it in place with the help of bolts. Then, tighten the bolts to the recommended torque specification using a torque wrench.

Step 8: Refill the Primary Oil

Lastly, you need to refill the primary oil by pouring the recommended amount of oil into the primary cover through the oil fill hole. Replace the drain plug and tighten it to the manufacturer’s torque specification.

Troubleshooting common issues with a compensator

As a compensator is so important to a Harley-Davidson bike, it starts developing issues and problems after regular use. The issues that it starts developing over time can affect the performance and reliability if not resolved. Here, you will get to know about some of the common issues with a compensator in a Harley-Davidson motorcycle and how to troubleshoot them –

#1. Excessive noise

One of the most common issues with the compensator of a Harley-Davidson bike is excessive noise. It can be caused by a wide variety of factors. One of the most common causes of excessive noise is a loose or damaged compensator nut. For troubleshooting this issue, riders need to inspect the compensator nut and tighten it to the manufacturer’s torque specifications if needed. Another possible cause of excessive noise will be worn or damaged compensator assembly, in which case the assembly will have to be replaced.

#2. Vibration

Another issue with the compensator is excessive vibration, and it is caused by various reasons. One of the reasons is a loose or worn out compensator nut, which can cause the compensator to “wobble” and generate excess vibration. For troubleshooting this issue, you will need to inspect the compensator nut and tighten it according to the manufacturer’s torque specifications. Another possible reason for excessive vibration is a worn or damaged compensator assembly, which will require replacement.

#3. Clutch slippage

In some cases, a worn-out or damaged compensator can cause the clutch to slip, which can lead to a loss of power and acceleration. For troubleshooting this issue, riders will have to inspect the compensator assembly for any signs of wear or damage. If the compensator is found to be worn or damaged, it will need to be replaced.

#4. Excessive wear or tear

Over time, the compensator on your Harley-Davidson motorcycle can experience excessive wear and tear because of the constant shock and vibration it absorbs. This wear can cause the compensator teeth to become worn or damaged, affecting their ability to absorb shock and protect the primary drive components. To troubleshoot this issue, riders should inspect the compensator teeth for any signs of wear or damage. If excessive wear is found, the compensator assembly will need to be replaced.

FAQs

What is a compensator on a Harley?

A compensator is a device that helps to reduce engine vibration on a Harley-Davidson motorcycle. It is located on the end of the crankshaft and uses a set of weights to offset the reciprocating motion of the pistons, resulting in smoother operation and improved ride comfort.

How does a compensator work on a Harley?

The compensator on a Harley-Davidson is a centrifugal device that uses weights to counterbalance the up and down motion of the pistons. As the engine revs up, the weights spin faster and move outward, creating a counterbalancing force that helps to reduce or eliminate engine vibration.

What are the benefits of having a compensator on a Harley?

A compensator on a Harley-Davidson can help reduce engine vibration, resulting in a smoother ride and improved comfort. It can also help reduce wear and tear on the engine and other components, resulting in improved reliability and performance.